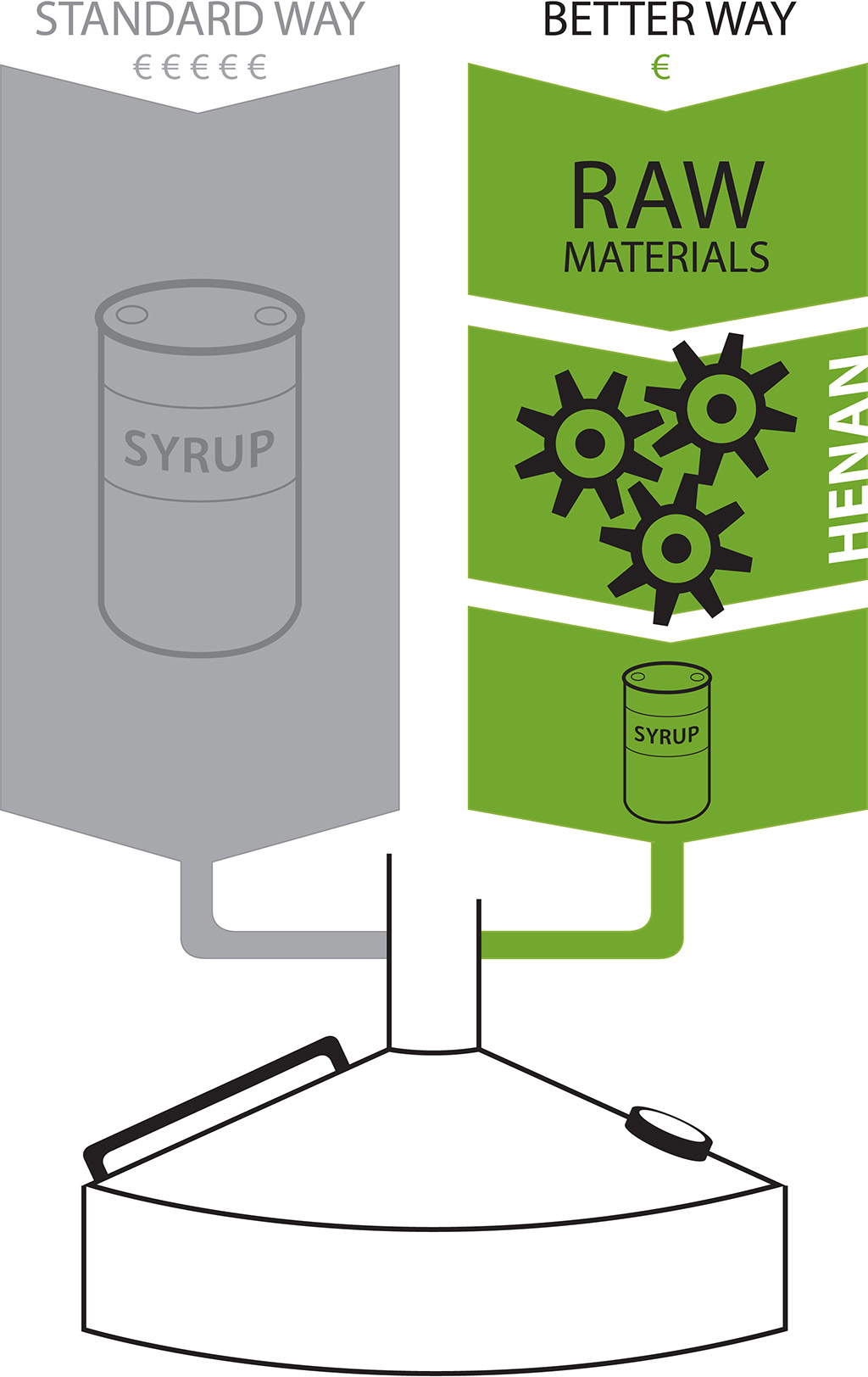

Syrup production for beer brewing

For the time being major syrup producers are not present in developing countries. Syrups for beer brewing have to be imported from far away resulting in high cost for the syrups used in the brewing process.

HENAN Food Systems developed THE SWEETNER, an innovative concept for in-line production of maltodextrins and starch sugars for brewing. Raw materials that can be processed vary from all types of starch to a wide variety of starch containing biomass. Depending on local-, and seasonal availability of raw material, brewers now have flexibility to choose individually for their most feasible option to convert local produced starch to the desired syrup type needed.

Pilot scale experiments executed by HENAN Food Systems resulted in proof of concept for in-line conversion of tapioca into high dextrose syrup and high conversion syrup with standard sugar and high maltose profiles. These syrups are widely used and immediately allow global entrance at breweries.

What we offer with our SWEETNER technology

| Good, stable microbiological quality of raw materials |

| A broad range of alternative raw materials can be used for syrup production |

| Cost price reduction for high maltose syrup |

| Our flexible concept may facilitate other innovations such as very high maltose syrup |

| Absence of beta glucans during mashing and lautering |

| Use of local produced starch sources possible |

| Our units are installed on the site of the customer and will be operated by the brewer |

Cost savings between 10% and 50% on raw material cost depending on the situation.